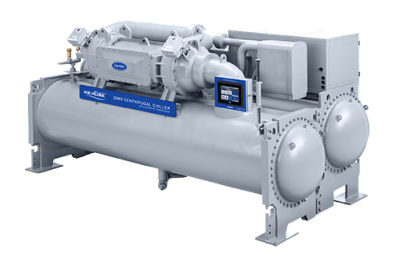

It’s essential to keep Electromechanical maintenance well In today’s changing industrial world, These systems are essential for operations in factories and commercial buildings, boosting productivity and ensuring everything runs smoothly. However, like any machinery, they can wear out over time. However, like any machinery, they can wear out over time. This is why electromechanical maintenance is so important. By understanding its value, businesses can ensure their equipment lasts longer, runs efficiently, and stays safe.

What is Electromechanical Maintenance?

Electromechanical maintenance involves the regular inspection, testing, repair, and upkeep of electrical and mechanical components in machinery and systems. It encompasses a wide range of activities designed to prevent system failures, optimize performance, and extend the life span of equipment. Key components under this maintenance include motors, generators, transformers, switchgear, and other critical machinery.

Benefits of Regular Electromechanical Maintenance

1. Enhanced Equipment Longevity

Regular maintenance greatly extends the life of electromechanical equipment. Parts like bearings, belts, and electrical connections can wear out over time. By finding and fixing problems early, businesses can prevent big breakdowns and avoid expensive replacements. This proactive approach saves money and keeps critical systems running smoothly.

2. Improved Efficiency and Performance

Efficient operation is paramount for any business. Well-maintained electromechanical systems operate at peak performance, ensuring that machinery runs smoothly and efficiently. This leads to reduced energy consumption, lower operating costs, and improved overall productivity. Regular maintenance helps in fine-tuning systems, optimizing their functionality, and eliminating inefficiencies.

3. Increased Safety

Safety is a primary concern in any industrial setting. Electromechanical systems, if not properly maintained, can pose significant risks, including electrical hazards, mechanical failures, and fire hazards. Routine maintenance helps in identifying potential safety issues and addressing them before they escalate. This not only protects the workforce but also ensures compliance with safety regulations and standards.

4. Reduced Downtime

Unexpected equipment failures can lead to costly downtime, disrupting production schedules and affecting business operations. Regular maintenance reduces the likelihood of such failures by ensuring that all components are in good working condition. Electromechanical service providers use advanced diagnostic tools and techniques to predict potential issues and address them proactively, thereby minimizing unplanned downtime.

5. Cost Savings

Although maintenance requires an initial investment, it leads to significant long-term savings. Preventive maintenance helps avoid costly emergency repairs and extends the life of equipment. Additionally, well-maintained systems use less energy, resulting in lower utility bills. Businesses can also enjoy lower insurance premiums since insurers often provide discounts for facilities with strong maintenance programs.

Key Maintenance Practices

To get the most out of electromechanical maintenance, businesses should follow a thorough maintenance plan. Here are some key practices:

Routine Inspections

Regular checks are essential to find wear and tear, loose connections, and other issues. Techniques like visual inspections, thermal imaging, and vibration analysis help spot problems early.

Predictive Maintenance

Predictive maintenance uses advanced technologies like IoT sensors and machine learning to monitor equipment. This method allows for real-time tracking of equipment health and timely fixes.

Corrective Repairs

When problems are found, fixing them quickly is crucial. Electromechanical service providers have the skills to make repairs efficiently, reducing any disruption to operations.

System Upgrades

Updating old components and systems can greatly improve performance and efficiency. Service providers can suggest and carry out upgrades to ensure your equipment stays current with the latest technology.

Electromechanical maintenance is an essential aspect of ensuring the longevity, efficiency, and safety of industrial operations. Regular maintenance practices, supported by skilled electromechanical service providers, can lead to enhanced equipment performance, reduced downtime, and substantial cost savings. By investing in proactive maintenance, businesses can safeguard their assets, optimize productivity, and achieve long-term operational success.

For electromechanical Services, trust the experts at Multiline. Our team of experienced professionals is dedicated to keeping your systems running smoothly and efficiently. Contact Multiline today to learn more about our services and how we can help you maintain your electromechanical systems for peak performance and longevity.

No comments yet.