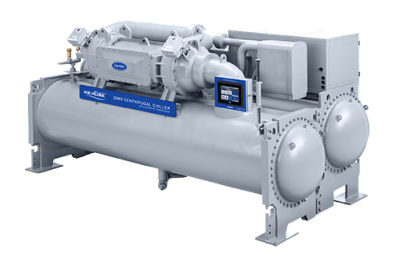

The HVAC (Heating, Ventilation, and Air Conditioning) industry is undergoing rapid changes driven by technological advancements, environmental concerns, and evolving customer demands. As an essential component of HVAC systems, duct manufacturing is at the forefront of these transformations. Here we will explore the future of HVAC duct manufacturing, highlighting the emerging trends and innovations that are shaping the industry.

The Evolution of HVAC Duct Manufacturing

HVAC duct manufacturing has come a long way from the traditional methods of fabricating ducts from sheet metal. Today, manufacturers are adopting advanced materials, automation, and sustainable practices to meet the growing demand for efficient and eco-friendly HVAC systems. The integration of new technologies is revolutionizing how ducts are designed, produced, and installed, paving the way for improved performance and reduced environmental impact.

Key Trends in HVAC Duct Manufacturing

1. Smart and Connected Ducts

The rise of the Internet of Things (IoT) is making its mark on HVAC duct manufacturing. Smart ducts, equipped with sensors and connectivity features, are becoming increasingly popular. These ducts can monitor airflow, temperature, and humidity, and even detect leaks or blockages in real-time. By providing valuable data, smart ducts enable proactive maintenance and optimization of HVAC systems, leading to enhanced energy efficiency and reduced operational costs.

2. Advanced Materials

The use of advanced materials is a big trend in HVAC duct manufacturing. Instead of just using traditional galvanized steel, manufacturers are now also using materials like aluminum, fiberglass, and composites. These new materials have several benefits: they are lighter, more durable, and provide better thermal insulation. Plus, they help improve indoor air quality by reducing the chances of microbial growth inside the ducts.

3. Customization and Modular Design

Customization and modular design are now key features in modern HVAC duct manufacturing. Thanks to digital design tools and automated processes, manufacturers can create ducts that fit specific building layouts and HVAC system needs. Modular ducts, which can be easily put together and taken apart, provide flexibility and convenience during installation and maintenance, helping to reduce downtime and costs.

4. Energy Efficiency and Sustainability

Energy efficiency and sustainability are at the core of current HVAC trends, and duct manufacturing is no exception. Manufacturers are focusing on producing ducts that minimize energy loss and enhance overall system efficiency. This includes the development of ducts with superior insulation properties and the use of environmentally friendly materials. Additionally, sustainable manufacturing practices, such as recycling and reducing waste, are becoming standard in the industry.

5. Improved Air Quality Control

As concerns about indoor air quality grow, HVAC duct manufacturers are innovating to address this issue. New duct designs incorporate features that enhance air filtration and purification, ensuring cleaner and healthier indoor environments. This is particularly important in commercial and healthcare settings where air quality is critical. Enhanced sealing techniques are also being used to prevent leaks and contamination within the ductwork.

The future of HVAC duct manufacturing is bright, with numerous trends and innovations driving the industry forward. As energy efficiency and indoor air quality continue to be top priorities, the HVAC industry will see even more groundbreaking advancements in duct manufacturing.

To stay at the forefront of HVAC duct manufacturing, it’s important to work with a company that adopts the latest trends and innovations. Contact Multiline today to discover how our advanced HVAC duct solutions can fulfill your requirements and enhance efficiency and sustainability in your projects.

No comments yet.